Radionuclide Drug Conjugates (RDC)

RDC Components:

• Targeting Ligand: Generally functions as a targeting moiety, typically a peptide, though it could also be an antibody or small molecule

• Radioisotope: The therapeutic or diagnostic payload that emits radiation to target and destroy cancer cells or provide imaging signals

• Chelator & Linker: The chelator tightly binds the radioactive isotope, while the linker serves as a bridge between the chelator and the targeting molecule

Non-radioactive RDC refers to the conjugate of a targeting ligand and a non-radioactive chelating agent.

One-Stop Non-radioactive

RDC CDMO Service

ChemExpress offers integrated services spanning from peptides, chelator & linker to non-radioactive RDC, enabling efficient scale-up and seamless technology transfer.

Extensive Project Experience

& Comprehensive Inventory

ChemExpress has over 1,000 linker syntheses experience and kilogram-scale chelators with technology experience, including DOTA, NOTA, TETA, and etc.

Compliant Production

Facility

ChemExpress has kilogram-scale GMP workshops for non-radioactive RDC, equipped with GMP DS&DP packaging.

Our Services

Partner with us to co-develop cutting-edge, efficient non-radioactive RDC process, from targeted ligands, linkers and chelators to compound synthesis. We provide customized solutions that simplify complex challenges, minimize risks, and accelerate the path to market — so you can make your innovations more efficient, faster.

Our Service Scope Includes

Ligand +Linker+Chelator Synthesis

- Process Parameter Optimization

- Stability Research on Unstable Intermediates

- Purification Method Research

- Impurity Control Strategy Research

- Process Characterization & Validation

Non-radioactive RDC Chelation Process Development

- Multiple Metal Chelation Methods, such as Ga, Lu, Cu, Y, and etc.

- Chelation Reaction Optimization

- Chelated Intermediates Stability Studies

- Non-labeled RDC Residue Control

- Metal Ions Residue Control

- Scale-up Chelation Process Development

- Seamless Transition to GMP Manufacturing

Why Partner with ChemExpress

Extensive Inventory

An inventory of over 1,000 linker syntheses experience and kilogram-scale chelators with technology experience, offering unmatched flexibility and scalability for non-radioactive RDC development

Advanced Analytical Platform

Over 300 precision instruments,specializing in the precise detection of chiral isomers, with multiple derivatization methods to ensure analytical precision and research quality

Robust Manufacturing Capacity

With GMP workshops, full-scale development from milligram (mg) to kilogram (kg), equipped with advanced SFC and special preparation platforms, as well as 3m2 freeze-drying equipment for diversified, high-efficiency production

Extensive Experience

Over 10 years of end-to-end expertise in peptide and small molecule from R&D to commercialization, supported by a professional team of specialists, possessing solid experience across two non-radioactive RDC CMC programs

Our Sites

R&D Sites

Manufacturing Sites

Manufacturing Site

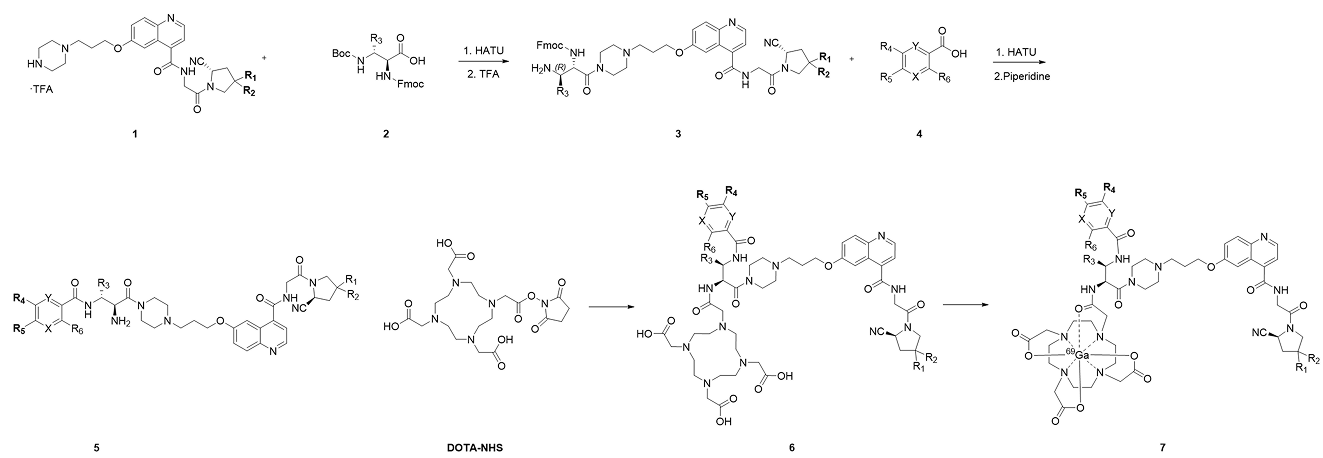

Case Study

In the synthesis , the original route yielded only 18%. By introducing a crystallization step to replace preparative HPLC purification, we improved intermediate purity and streamlined the process. The overall yield increased to 38%, final purity reached 99.5%, and material and production costs were reduced by 72% and 68%, respectively.

FAQs

ChemExpress and Nanjing University have jointly established Nanjing Xtalexpress R&D Center featuring crystal sponge technology. The porous framework of specific sponges can orderly capture sample molecules, which are then visualized by X-ray diffraction to determine structure and chirality. Only nanogram-scale samples are theoretically required. Additionally, for chiral intermediates or non-radioactive RDC with crystalline forms, Micro-ED (microcrystal electron diffraction) serves as an effective complementary method—providing a more convenient and efficient approach for RDC structure characterization.